A Guide to Proper Tank Mixing

Tank mixing various combinations of pesticides, fertiizers and other liquid products is a common practice in agriculture that can save growers a lot of time. It allows for the treatment of pests, weeds and disease all at once but proper mixing guidelines must be followed. Just as easily as tank mixing can save you time, incorrect tank mixing can cost you time and money while you clean gels, solids, and hard-packed sediments from your hydroponics setup. In severe cases, improper spray tank mixing can damage your crop.

Physical incompatibility issues related to improper tank mixing range from clogged screens caused by physical and chemical incompatibilities between mixed agents to excess foaming. Clogged screens can affect spray pressure, product efficacy and eventually lead to crop damage. Here are a few examples of what could happen when you don’t follow the correct tank mixing order:

- Dry products cannot disperse or suspend properly in the solution. When this happens, silt will form a cake-like layer along the bottom of the tank or form particles that can clog screens.

- Liquid solutions may curdle and thicken into a paste or gel that makes it difficult to clean the tank.

- Oil residue coatings or films could collect on tank walls and rubber hoses.

- Active ingredients may separate into distinct layers in the spray tank.

- Excess foaming caused by trapped air in the tank mixture.

The effect of a chemically incompatible tank mixture may not always be clear, but it can negatively affect spray quality, product uptake, and leaf surface retention of your application. Visible crop damage may occur a few hours to several days following an application. Sometimes, reduced efficacy is the only noticeable effect of chemical incompatibility, but this calls for an increase in applications which can decrease yield, harm crop quality, or both.

Following the proper tank mixing order for when using multiple products can help prevent chemical incompatibility.

Proper Tank Mixing is Essential for Healthy Crops

It’s not just a matter of which products can be safely tank mixed together, but also in what order to add different formulations. Successful herbicide, pesticide and fertilizer applications start with reading labels and then adding them in the correct order. For example, mixing an oil adjuvant with an herbicide might increase cuticle penetration, but it could also affect herbicide activity that leads to scorching on crops.

The two most common carriers used for applying pesticides are water and liquid fertilizers. Carefully read our spray tank mixing guide below and labels on your products for any additives and follow the recommendations exactly.

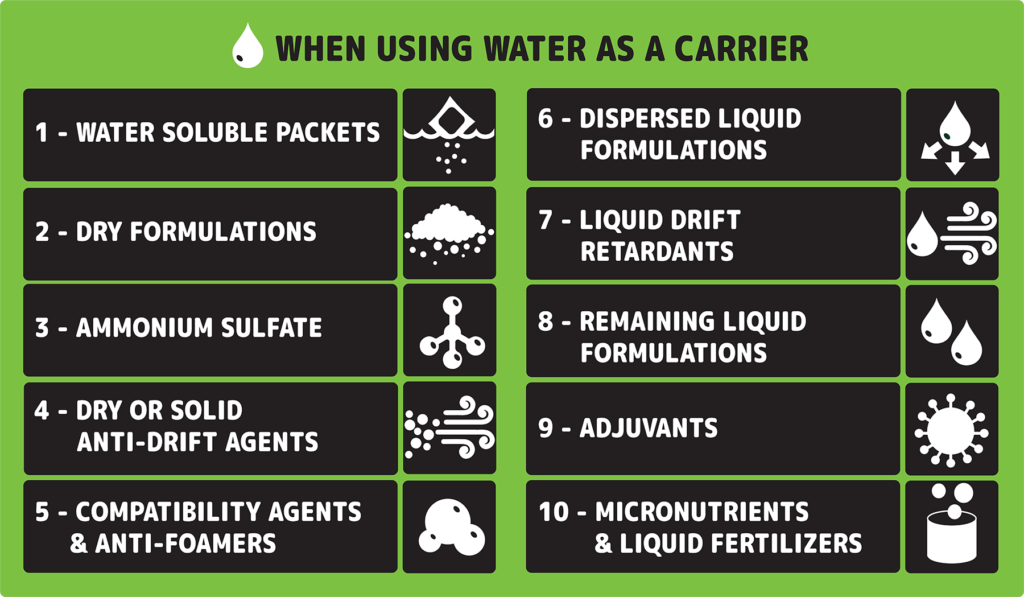

When Using Water As a Carrier

Water is typically better for tank mixtures since most products are designed to be used with water. When you use water as a tank-mix carrier, follow this general mixing order:

- Read all product labels.

- Shake all liquid product containers.

- Fill the spray tank with 50 percent of the required water volume.

- Start the agitation and continue through the mixing process.

- Add products based on formulation type in the order shown in the table below.

- Wait three to five minutes before adding products after dry formulations.

- Add remaining water.8. Measure the pH of your spray solution.

- Measure the pH of your spray solution.

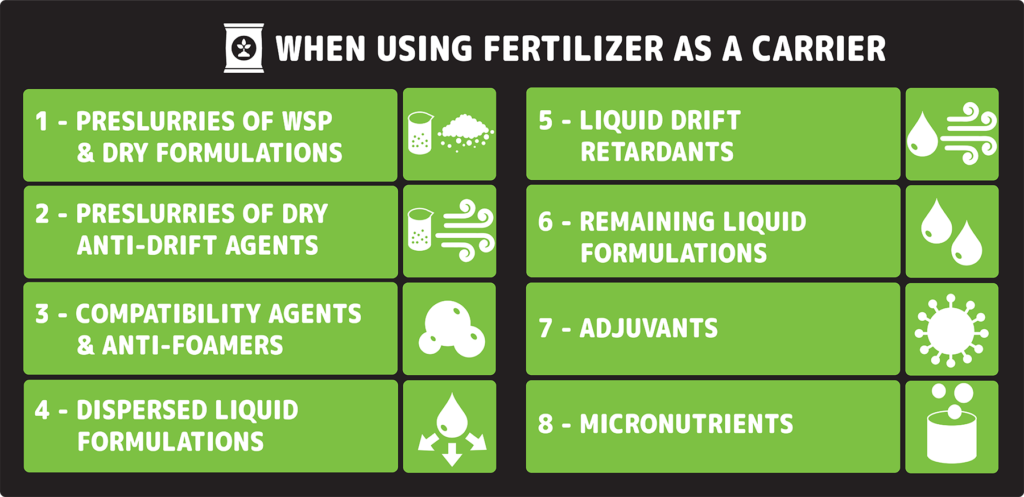

When Using Fertilizer as a Carrier

Since compatibility issues are more likely to occur using liquid fertilizer, be cautious when you mix multiple products. When you use a liquid fertilizer (32-0-0, 28-0-0, 10-34-0) as a tank-mix carrier, follow this general mixing order:

- Read all product labels.

- Shake all liquid product containers.

- Fill the spray tank with 50 to 75 percent of the required fertilizer volume.

- Never premix products in an inductor.

- Add products based on formulation type in the order shown in the table below.

- Add remaining fertilizer to the sprayer.

- Inspect solution for signs of incompatibility such as separation.

- Continue to agitate mixture until it is applied.

Conclusion

With increasing interest in recent years in mixing various pesticide products to provide more effective control of weeds, it’s crucial for growers to follow the proper tank mixing order.

To ensure all your products will mix well, we highly recommend you conduct a jar test before mixing in the tank. Instead of mixing, and potentially wasting, large volumes of products in the spray tank, a jar test allows you to test a small amount of product combinations for compatibility first.

Here are a few more jar test considerations:

- It’s fine to use the same products in your spray tank from one year to the next. However, be aware that manufacturers often change the inert ingredients in their products. These changes might alter how the product interacts during mixing.

- It is important to use the same water source and temperature for the jar test you will use in your tank mix. You should actively practice this for all ingredients, since bulk tanks may be colder during mixing than just a small sample from a 2.5-gallon jug mixed indoors.

- Keep track of problem tank mixes (so you avoid repeating them) and successful mixtures for easy reference in the future.

Tips on How to Add HYGROZYME, HYSHIELD and HYCLEAN to the Mix

HYGROZYME and HYCLEAN are fully compatible with all nutrients and supplement programs; however, we recommend watching out for your pH!

HYCLEAN has a neutral pH and, with such a low dilution ratio (1 mL per gallon), will not change or affect the pH of the nutrient solution. HYGROZYME also has a neutral pH; therefore, you can mix them together and then add them to your nutrient solution. For optimal results, the final pH of your nutrient solution should be within 5.5 to 7.

When it comes to HYSHIELD, even though it is compatible with HYGROZYME, HYCLEAN and all water-soluble nutrients (and you can add it to your reservoir after a successful jar test), we strongly recommend applying it as a foliar. Growers have seen amazing results when applying it directly to the plants!

For more info on how to use our products, check out our Feed Calculator page.

And don’t forget that there are great tools out there that can assist you with the proper tank mixing sequence of products—like the free app from Precision Laboratories, which is recommended by Ontario’s Ministry of Agriculture, Food and Rural Affairs.

- Hydroponic Gardening Tips and Tricks

- HYGROBEN™ and the Direct Mechanisms of Bacillus Species

If you follow us on social media, you’ve probably seen or heard the… Read more: HYGROBEN™ and the Direct Mechanisms of Bacillus Species

If you follow us on social media, you’ve probably seen or heard the… Read more: HYGROBEN™ and the Direct Mechanisms of Bacillus Species - The Benefits of Using HYGROBEN™ and HYGROZYME® Together

SIPCO Innovations, the manufacturer of HYGROZYME®, is excited to announce the launch of its… Read more: The Benefits of Using HYGROBEN™ and HYGROZYME® Together

SIPCO Innovations, the manufacturer of HYGROZYME®, is excited to announce the launch of its… Read more: The Benefits of Using HYGROBEN™ and HYGROZYME® Together

- On October 3, 2022